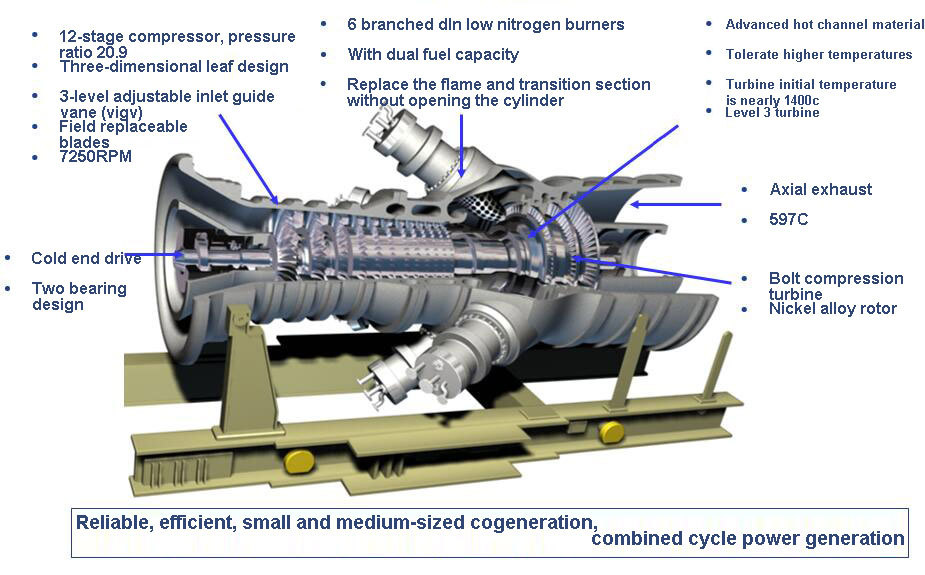

Gas turbine 6f.01

6f.01 Technical data

| Gas turbine output (MW) | 50.5 |

| Gas turbine efficiency (%) | 37.9% |

| Compressor | Level 12 |

| Burner | DLN 2.5 |

| Power turbine | Level 3 |

| Speed (RPM) | 7250 |

| Exhaust temperature (°C) | 597 |

| Exhaust flow rate (t/h) | 452 |

| 1x1 combined cycle net output (MW) | 73 |

| 1x1 combined cycle net efficiency (%) | >55% |

6f.01 Gas turbine structure – reliable, efficient, 50mw

6f.01 gas turbine technical characteristics

Ge's f-class gas turbines have more than 1,200 units in operation, with cumulative cumulative performance of 50 million hours and 1 million starts.6f.01 Adheres to the most experienced f-class gas turbine technology in the gas turbine industry.Has the following technical characteristics:

Axial exhaust, cold end drive

Inverter start

High combustion temperature (near 1400 ° C)

High exhaust gas temperature (over 600 ° C), ideal for cogeneration

In small and medium-sized gas turbines, combined cycle efficiency is the highest

12-stage compressor design (using the design of the compressor in the ge aircraft engine and the ge oil and gas industry)

3-stage adjustable inlet guide vanes for improved partial load efficiency

Field replaceable blades for easy access and maintenance

Dry low nitrogen (dln) combustion system

An manhole is provided for the combustion chamber to facilitate maintenance or replacement of the flame tube and transition section

Level 3 turbine

Full three-dimensional aerodynamic design

The first stage moving blade is a single crystal material; the oriented crystal and the equiaxed crystal material are applied to the remaining moving leaves and vanes

Nickel alloy turbine rotor for longer life (144,000 hours of rotor overhaul)

Improved thermal barrier coatings, gaps and seals

Turbine nozzles and buckets are air cooled

The gas turbine and auxiliary machinery are modular in design, easy to install, commission, repair and maintain.

GE's patented gas turbine Mark VIe control system can also be used as a DCS control plant

Previous Page

Next Page